1

A na-ejupụta ibe PA6 ahụ n'ahịrị gbazere ma jiri nwayọọ nwayọọ gbanye ya site na ibe kpo oku.A na-agafe granules na-agbaze n'ikpeazụ site na nrụgide ọrụ dị elu nke ịghasa na isi na-agbagharị ma pịa ya.

2

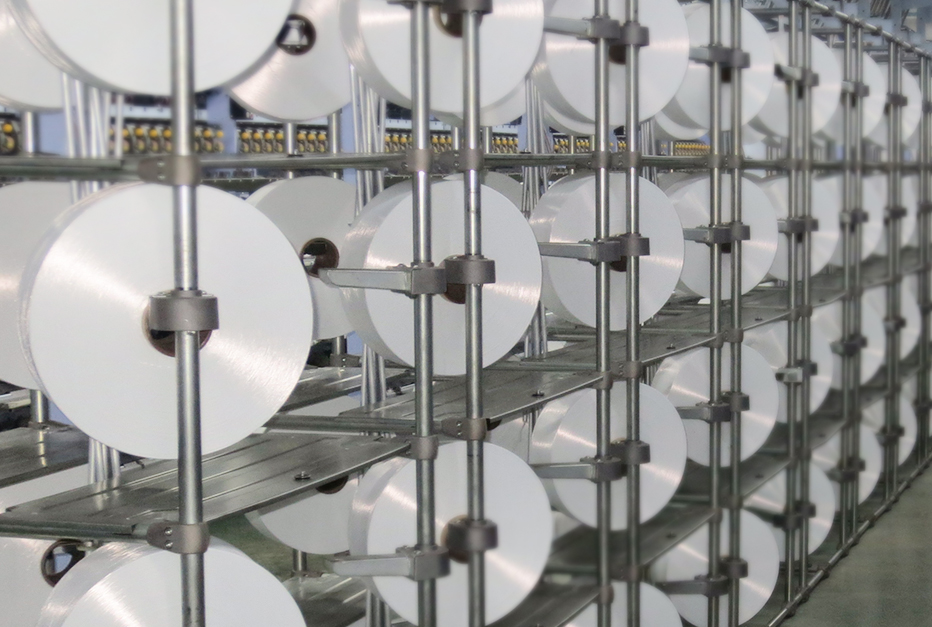

Nfuli nfuli na-pịa polymer gbazee site na obere spinnerets micro-mma n'okpuru nrụgide dị oke elu.A na-ejikọta filament naịlọn ndị a na-emepụta n'ime yarn, na-adọta n'elu godets na ọnya site na iji winder.

3

Yarn na-ebute ụzọ (POY) bụ ihe mmalite maka ụdị ejiji, egwuregwu, arụ ọrụ na akwa ụlọ.A na-ejikarị ya na texturizing iji mee yarn textured ma nwee ike iji ya na-ese warping maka ịkwa akwa na ịkwa akwa akwa.N'ebe a na JIAYI anyị na-agbaso ederede POY n'ụdị DTY(Draw Textured Yarn).

4

The eFK bụ igwe DTY nke ọma na-arụ ọrụ nke ọma na teknụzụ nri godet kachasị ọhụrụ na uru maka mma nylon yarn kacha mma.Texturing bụ ngwụcha ngwụcha nke na-agbanwe yarn ọkọnọ POY ka ọ bụrụ DTY wee bụrụ ngwaahịa mara mma na nke pụrụ iche.N'oge ederede, na-ebute ụzọ. A na-akpachapụ yarn (POY) na-adịgide adịgide site na iji esemokwu.N'ihi ya, a na-abawanye nrịbama na njigide okpomọkụ;naịlọn yarn na-enweta aka na-atọ ụtọ, ebe a na-ebelata ikuku okpomọkụ n'otu oge.

5

N'oge ọ bụla nke mmepụta bụ nyocha siri ike tupu usoro na-esote;

Site na polymers enwere IV, pasent ọdịnaya mmiri na nyocha otu njedebe.

Maka POY, enwere nyocha nke ọma nke ndị agọnarị na filament.

N'ime usoro ederede, ọkwa POY, luster, BS, E% na ike na-aga ule siri ike.

N'ime usoro ntụgharị, nlele anya bụ maka ike ngwugwu, nha ngwugwu na ntụgharị ntụgharị.

N'ikpeazụ, maka ịlele DTY, anyị na-anwale akụrụngwa anụ ahụ, dị ka ike ịnwụ anwụ, ike siri ike, ọdịnaya mmanụ, mgbede, elongation, mkpirisi mkpọ, mmiri na-esi ísì ụtọ ...